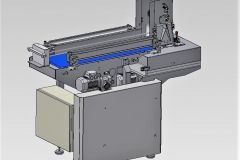

Machines for handling of packing materials

This type of machine is typically included as part of a production line where the finished product is packaged in a plastic packaging, such as a tray, which is subsequently foiled.

For example, the machine can perform the function of separating the individual packaging items and transport them to a conveyor that leads them on to a station where the product is filled in.

Møn Maskinbyg provides this type of solutions to both Danish and foreign companies in the food industry, the pharmaceutical industry, and the packaging industry.

- Blister and plastic trays are separated and carried forward to a robot or a filling system with up to 85 trays per minute.

- Metal packaging for tinned food is separated and carried forward for further processing or filling with up to 160 packages per minute.

- Buckets and pails of plastic or metal are separated from stack and carried forward for further processing or filling with up to 80 items per minute.

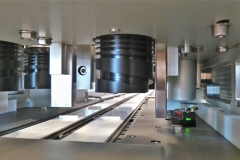

Machinery for shaping and handling of metal packaging

These machines do often have several features but common to them is that they handle items made of metal in a production line. Either from a single operation or several operations in one work procedure. The machines range from simple conveyors to more complex machines that for example manufacture tobacco tins. Curling, threading and trimming are typical tasks, which are handled by this type of machine.

- Møn-O-Mate machines metal tins and lids by trimming, curling, beading, bending, threading, or milling grips in several stations.

- The stacker system is able to stack both round and rectangular metal tins by up to 160 tins per minute per line.

- Stacking systems for metal lids are able to stack up to 560 items per minute.

- Transport systems such as downpipes and turning systems for orientation and positioning of all kinds of metal packaging.

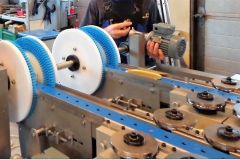

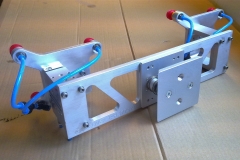

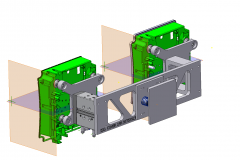

Equipment for handling of items at injection moulding machines

The machines for the handling of injection moulded items are typically devices that grab hold of and/or place an item in the mould in order to subsequently take them out when the moulding process is finished. In addition, this category of equipment includes all associated “support functions” such as electronic surveillance, sorting, further handling, and much more.

- Specially designed gripper devices for robots equipped with pneumatically or vacuum controlled grippers, both with or without electronic surveillance.

- Gripper units for loading items “in moulding” in plastic moulds with subsequent removing of finished items.

- Buffer systems for handling, sorting, stacking, orientation and quality control of all kinds of items.

- Machines for sorting, orientation and assembly of multiple components placed directly on or outside injection moulding machines.

Machines for forming and machining of products in industrial bakeries

These machines are manufactured to perform a wide variety of tasks in the production in industrial bakeries. The tasks range from preparation of dough, including cutting and forming, to separating and packing of the finished products.

- Separating and cutting of dough rolls with subsequent laying out in specific patterns.

- Alignment and handling of bread and cakes for preparation before entering into packaging systems.

- Separation of bread or cakes and cutting of patterns with ultrasonic knife.

- Filling of tins, blister trays, boxes and pallets